Products

Measuring instruments

To achieve quantitative evaluation and quality improvement of processed workpieces, measuring instruments are indispensable. We address the challenges of measurements in the field with multi-sensor measurement systems capable of optimal measurement with video images, lasers, and touch probes, geometric tolerance software for comprehensive management of dimensions, shapes, and positions, precision digital levels for measuring the flatness of granite tables and straightness of machine guideways, cutting tool geometry inspection systems ensuring reliability in measurements on the shop floor, and pin gauges for quick measurement of hole diameters.

Dimensional and geometry measurement

As part of quality control, verification of whether the dimensions, shapes, positions, and orientations of products, such as length, angles, and heights, meet specified criteria is conducted. We have a lineup of software for determining geometric tolerances using CAD models and measurement data, to multi-sensor measurement systems. Non-contact video measurements suitable for precise measurements without leaving marks, lasers for measuring mirror surfaces or steep slopes, and touch probes suited for point and surface measurements meet diverse measurement needs.

-

OGP

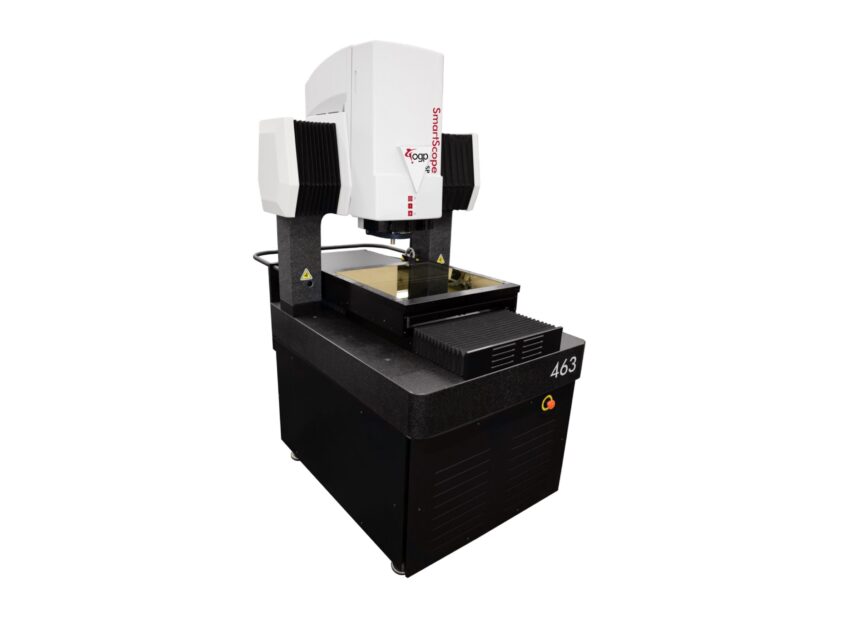

SmartScope ZIP Series

3D multi-sensor measurement system

OGP

SmartScope ZIP Series

3D multi-sensor measurement system

-

OGP

SmartScope VANTAGE Series

3D multi-sensor measurement system

OGP

SmartScope VANTAGE Series

3D multi-sensor measurement system

-

OGP

SmartScope SP Series

3D multi-sensor measurement system

OGP

SmartScope SP Series

3D multi-sensor measurement system

-

VIEW

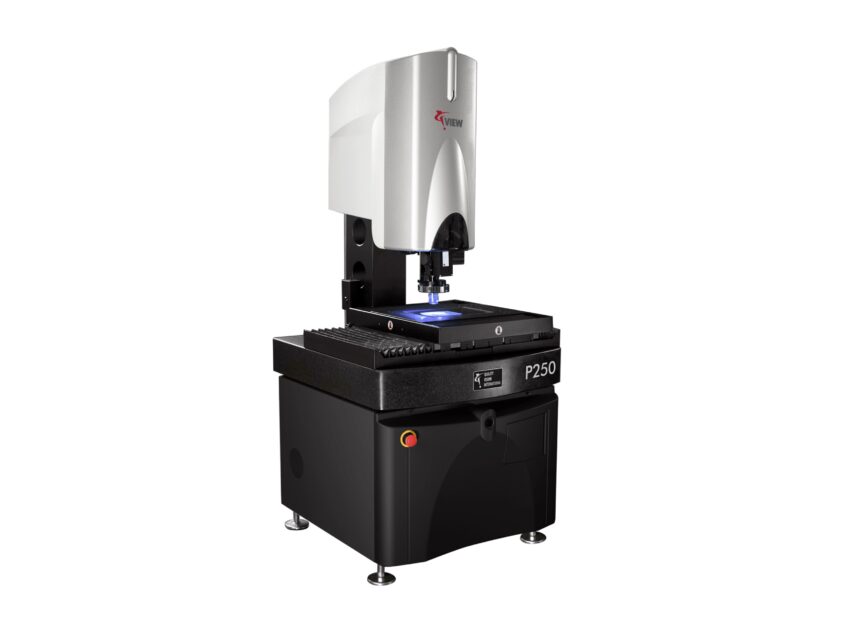

Pinnacle/Summit

High performance metrology system

VIEW

Pinnacle/Summit

High performance metrology system

Inclination measurement

Inclination measurement is necessary in a wide range of industries such as transportation, construction, civil engineering, and machinery. This includes angle measurement for aircrafts and maritime radar systems, monitoring surveys for bridges, dams, and antenna base stations, inclination management for road construction, leveling of machinery, flatness measurement of granite tables, straightness measurement for semiconductor device stages and coordinate measuring machines, and precision management through pitch and roll measurement of machine tools. Levels play a crucial role in many applications.

-

WYLER

BlueLEVEL

High precision inclinometer

WYLER

BlueLEVEL

High precision inclinometer

-

WYLER

Clinotronic S

Digital inclinometer

WYLER

Clinotronic S

Digital inclinometer

-

WYLER

Clinotronic PLUS

Digital inclinometer

WYLER

Clinotronic PLUS

Digital inclinometer

-

WYLER

ZEROTRONIC 3/C

Inclination measuring sensor

WYLER

ZEROTRONIC 3/C

Inclination measuring sensor

Inspection equipment

We offer a wide range of inspection equipment to support production in various fields. This includes geometric analysis to improve the static accuracy of machinery, wheel balancers to reduce grinding chatter and enhance dimensional accuracy, wheel presetters to improve the operating efficiency of grinding machines, spindle centering systems to prevent damage to lathe tools, spherical pin gauges capable of quick and precise hole diameter measurement even at a 120-degree insertion angle, and user-friendly and easy-to-use optical microscopes.

-

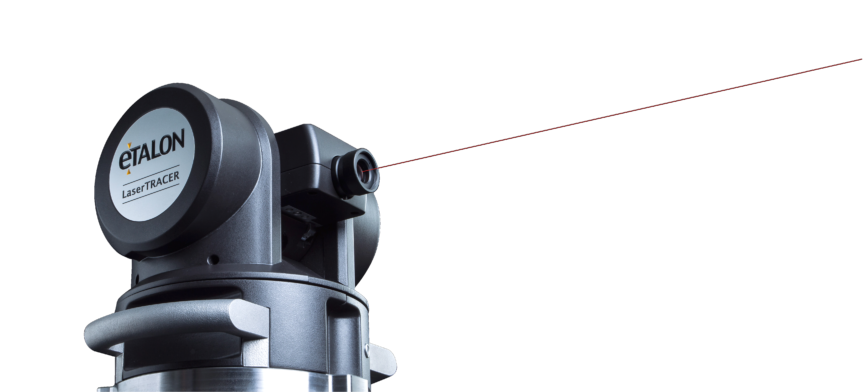

ETALON HEXAGON

LaserTRACER-NG

Self-tracking laser interferometer

ETALON HEXAGON

LaserTRACER-NG

Self-tracking laser interferometer

-

ROLLOMATIC

BMT200-OP40

Wheel balancer

ROLLOMATIC

BMT200-OP40

Wheel balancer

-

WIBEMO

Mowidec-TT

Spindle centering system

WIBEMO

Mowidec-TT

Spindle centering system

-

SPHERIDUR

SPHERIDUR

Plug gauge

SPHERIDUR

SPHERIDUR

Plug gauge